Pressure washers are a powerful cleaning and surface prep tool for the professional painting contractor. For this article, we asked the experts at Sherwin-Williams and Mi-T-M, a leading manufacturer of pressure washers and other high quality industrial equipment, for tips on best practices and equipment selection.

As a starting point, ask yourself three questions about the type and volume of work you expect to be doing, as well as the time demands of your jobs.

1. Is time a factor?

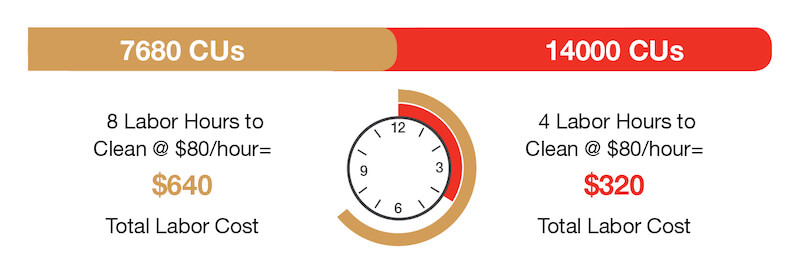

Time means money on every paint job. A heavy-duty pressure washer can cut cleaning times in half. Shorter cleaning time means less labor, which equals more productivity.

The important term to know here is “cleaning units.” Cleaning units provides a measure of performance – efficiency – to compare one unit to another. Cleaning units is calculated by multiplying PSI (pounds per square inch) and GPM (gallons per minute). Example:

- 3200 PSI x 2.4 GPM = 7,680 cleaning units

- 4000 PSI x 3.5 GPM = 14,000 cleaning units

The 4000 PSI unit cleans 50 percent faster than the 3200 PSI unit. Not better, but faster. Cleaning units do not determine quality of the unit. Quality is determined by the type of pump and the components of the pump.

2. How much pressure washing will you be doing each week?

Pressure washers are available in belt drive and direct drive models. The amount of work you expect to do will determine which type will best serve your usage needs.

- Belt drive: Most commonly found on industrial models, a belt-driven pump is ideal for cleaning applications requiring 20 or more hours of use per week. The belt connecting the engine or motor with the high-pressure pump dissipates the heat and vibration, minimizes the wear and thus the repair on key components, and extends the life of the pump by reducing the RPM demand.

- Direct drive: For applications not requiring more than 20 hours of use per week, direct driven pumps are more commonly used. The pump is directly coupled to the engine or motor causing the pump to spin twice as fast as the belt drive models. Although these models are not recommended for heavy, consistent usage, they are a lower-cost alternative to belt-driven models.

3. What type of contaminant needs to be removed?

Your specific job needs will also help you determine whether to use a hot or cold water pressure washer.

- Cold water: Cold water pressure washers are ideal for removing dirt and mud from most any surface – decks, siding, concrete, etc. For more cleaning power, there are accessories available that work with a cold water pressure washer, increasing cleaning power and decreasing cleaning time.

- Hot water: However, to clean any surface that needs to be degreased, hot water is a must. Cold water pressure washers cannot remove grease and oil effectively. You wouldn’t think of washing your greasy hands with cold water and the same principle applies to pressure washing. Also, if you operate cold water equipment more than a few hours a week, you should closely consider the labor savings that could be realized by switching to a hot water pressure washer.

https://youtu.be/LO-UeaXKoxU?controls=0”

Pro tips: safety and maintenance

A pressure washer is a great tool if used properly. Read your operation manual thoroughly to ensure safe operation, and wear proper eye, face and hand protection when operating the equipment. Some additional tips from Mi-T-M:

- Make sure all guards and shields are in place and in good working order and check oil levels before every use.

- Attach nozzles and/or accessories completely before starting the machine, and keep hands and feet clear of the cleaning nozzle at all times.

- Wash a small test area prior to starting your cleaning task.

- Direct the water at a downward arc when cleaning wood substrates. Spraying head-on can damage wood siding and decks.

- Keep the wand and water jet at least six feet away from electrical wires, service boxes and entrances. A shock from service wires can be deadly.

- Don’t hold the nozzle too close to the surface or too long in one spot – the strong jet will gouge wood, dent aluminum side, erode stucco, and blast mortar out of joints in brick walls. Likewise, do not point the wand directly at windows, for obvious reasons.

- Don’t leave the nozzle in a closed position for more than a minute or two while the equipment is running. The pump may overheat. Also, don’t fill the fuel tank while the engine is running or still hot, and don’t try to repair a leak in the hose or connection while the system is under power.

- Don’t pressure wash from a ladder – you’ll need both hands to control the wand. When you turn the machine on, it has a hefty kickback, which can knock you off balance. Instead, use an adjustable extension wand to reach high places.

Learn more

A wide range of pressure washers is available at Sherwin-Williams, categorized for residential repaint, property management, commercial and industrial applications. Stop in at your local store for expert guidance on the best equipment for your project needs.

For an interactive side-by-side comparison of four of the most popular pressure washers for pro painters, visit this website developed by Mi-T-M and Sherwin-Williams.

Sherwin-Williams is your single source for all your painting equipment needs. Get a full overview with their free 39-page downloadable PDF, the 2020-2021 Sherwin-Williams Equipment Reference Guide.